The New Coastal Highway: many an exploit between land and sea

24 July 2018 - Projects update and handover - France

Spectacular by virtue of its scope and technical complexity, the New Coastal Highway comprises France’s longest viaduct and 6.7 km of embankments. Between now and 2020, it will give Reunion Island a coastal link that is strategically important for the local economy and for the safety of people on the island.

The new highway will replace the north-west coastal road currently in service, which is the island’s most strategically important transport corridor. Used by 60,000 vehicles a day, it links Saint Denis, the administrative capital, and the cities of La Possession and Le Port, in which are concentrated one-third of the island’s manufacturing, transport and service companies.

Located at the foot of a cliff, the existing road is renowned for the danger it represents in terms of falling rocks and waves crashing over it. Although it is the main transport infrastructure for both people and freight, it has to be closed for an average of two months a year in order to protect users.

Launched by the regional authority, French government and European Union, the New Coastal Highway (NCH) will be a 12.5 km three-lane dual carriageway, much of it built at sea.

Running parallel to the coast at a distance of between 80 metres and 300 metres from the shore, the new road has three interchanges, six sea embankment sections and a 5.4 km prestressed concrete viaduct.

Ultimately, it will make the existing corridor safer and unblock local trade. It will also foster sustainable public transport mobility and give fresh momentum to the island’s economy.

A VIADUCT BUILT ON LAND TO CROSS THE SEA

“We’re building as many elements of the infrastructure as possible in two purpose-built prefabrication plants, and then transporting them offshore,” explains VINCI Construction Grands Projets’ Francis Guinchard, project director of the coastal viaduct consortium.

This radical choice for building the viaduct was made because of:

- the need to protect marine flora and fauna;

- the sensitive environment and difficult – sometimes extreme – sea conditions.

But it’s a construction method that calls for extraordinary logistics due to the size and weight of elements to be transported.

Zourite (the Creole word for “octopus”) is the name of the mega-barge that is key to the construction of the sea viaduct. Specially designed for the project, it was built in Poland and is as big as a soccer pitch.

The viaduct deck sections are assembled using a specially designed launching girder that is 278 metres long and weighs 2,600 tonnes. The girder, designed to withstand 240 km/h cyclonic winds, advances as the deck is installed.

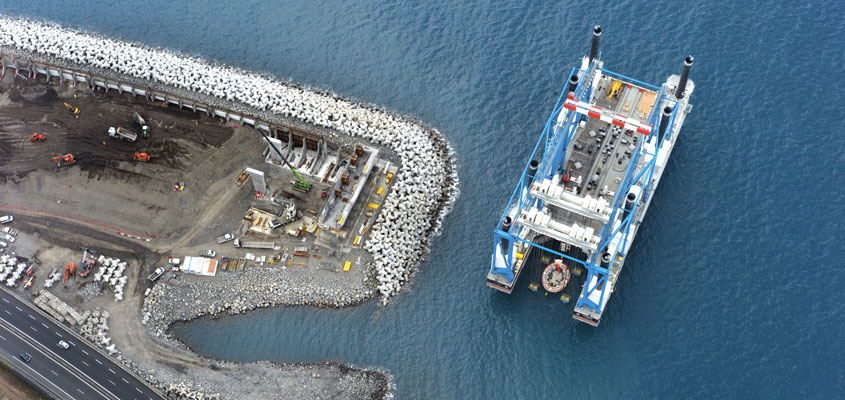

AN EMBANKMENT TO SHIELD AGAINST THE OCEAN

The teams are also building the NCH embankments, which are designed to withstand a 100-year cyclonic swell. The embankments are protected from erosion by a hard shell made up of 38,500 AccropodesTM. The role of these enormous blocks of concrete, weighing a total 780,000 tonnes, is to break up the swell by dispersing it. Their installation on the embankments is in accordance with very strict rules. It is done by specially trained teams using cranes. Lifted to a height of 60 metres, each block is equipped with a sort of “black box” that transmits its spatial configuration via GPS, enabling it to be positioned with pinpoint accuracy.

INNOVATION TO PROTECT ANIMAL LIFE

Reunion Island’s marine and submarine environment is home to over 3,500 protected species. The NCH offshore worksite is making every effort to protect these natural assets, for which the island is famous.

To limit the submarine propagation of works-related noise, which is harmful to cetaceans, sound barriers made of curtains of bubbles are deployed in areas of offshore works.

To protect submarine animal life and coral reefs, the water’s pH and oxygen level are constantly measured during concreting phases. Levels of suspended particulate matter are checked several times a week in environmentally sensitive areas such as coral reefs near the viaduct.

PROJECT PARTICIPANTS

VINCI is participating in the construction of the NCH through two consortiums: one for the viaduct, the other for the embankments and La Possession interchange at the western end of the highway, near the island’s trading port.

The viaduct consortium comprises VINCI Construction Grands Projets (leader) and Dodin Campenon Bernard, along with Bouygues Travaux Publics and Demathieu Bard Construction. The embankments and interchange consortium consists of VINCI Construction Terrassement and two of the island’s companies: SBTPC, a local subsidiary of VINCI Construction Dom-Tom, and Bouygues subsidiary Grands Travaux de l’Océan Indien (GTOI).

Subscribe

100 years: the life cycle for which the structure is designed and the materials selected

300,000 m3 of concrete and 52,000 t of steel used to build the viaduct

4,500 t: the weight of just the lower part of the viaduct piers

Almost 3,000 local jobs created by the project

VINCI Construction has been operating on the island for 60 years

Media contacts

Stéphanie Malek

Tel: +33 1 57 98 66 28

media.relations@vinci.com