What happens afterwards? The lifecycle of renewable energy facilities

Analysing the lifecycle provides a clearer insight into the real impact that green energy production facilities have on the environment. Lifecycle assessments are a key tool for taking another step towards the energy transition.

In the same report

Storage: the cornerstone for developing renewable energy

With the construction of new solar power plants and wind farms and the design of power transmission lines showing no signs of slowing down, the question of the environmental impact caused by these infrastructures warrants a closer look at their entire lifecycle. At a time when the first solar panels are becoming obsolete and wind turbine blades need replacing, the lifespan of renewable energy installations is now coming in for greater scrutiny, along with their durability and recyclability.

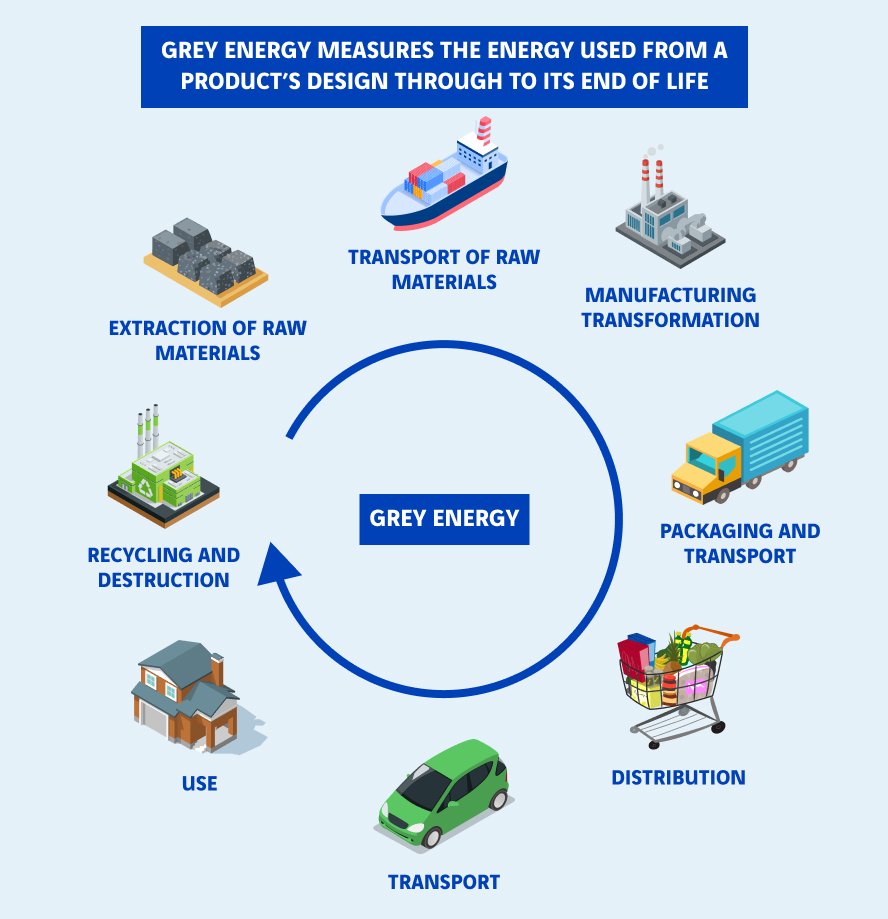

What exactly is grey energy?

Unlike the direct and easily measurable energy that is required to create a product, building or factory, grey energy takes account of all the “hidden” energy needed from cradle to grave.

Therefore, when calculating the grey energy of a product or facility, various factors are included in the equation, such as its early design, the extraction and transportation of all the raw materials used and their transformation into the finished product, packaging, marketing of the product and any transport to its place of installation or sale, its installation, use and maintenance, and finally its destruction and recycling.

Taking grey energy into consideration provides a more insightful understanding of the actual environmental impact of any product, facility or infrastructure.

From design to production: the environmental cost of renewable energy facilities

A positive outcome for solar power

When it comes to renewable energy (RE), solar power adoption is rising especially fast around the world. This may be good news for the greenhouse gas emissions from energy generation facilities, but it raises a number of question marks about their production and disposal at a time when the first generations of solar panels, which were designed around 30 years ago, are now coming to the end of their service life.

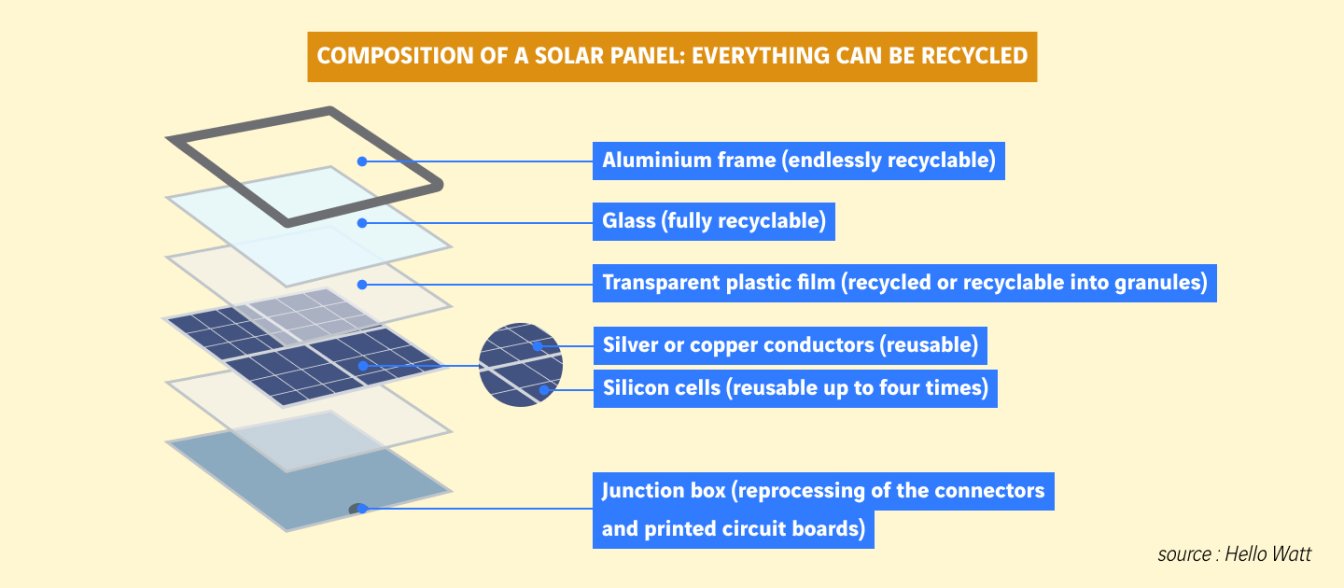

Most solar panels are made from silicon, i.e. the raw material for photovoltaic cells. Although silicon can be found everywhere on Earth, it is not in a pure state, so it needs to be refined or extracted from quartz or sand using an energy-intensive reduction process. Solar panels also contain aluminium (in their frame), glass, plastic for encapsulating the cells, and copper or silver connections.

From extracting the silicon to manufacturing the panels, between 75% and 97% of photovoltaic production is concentrated in China, and most of these production sites are powered by fossil fuels. Consequently, when calculating a PV system’s carbon footprint, consideration should not only be given to the energy used in manufacturing the panels, but also to the energy involved in shipping them from China. A few other manufacturers are based in the United States, Germany and France, but their prices are often not competitive enough to gain a real foothold in the international scene for the time being.

Once a solar panel has been produced, its lifespan is around 25 years. When panels reach the end of their life, they tend to be too obsolete to be reused, but 95% of their components can potentially be recycled.

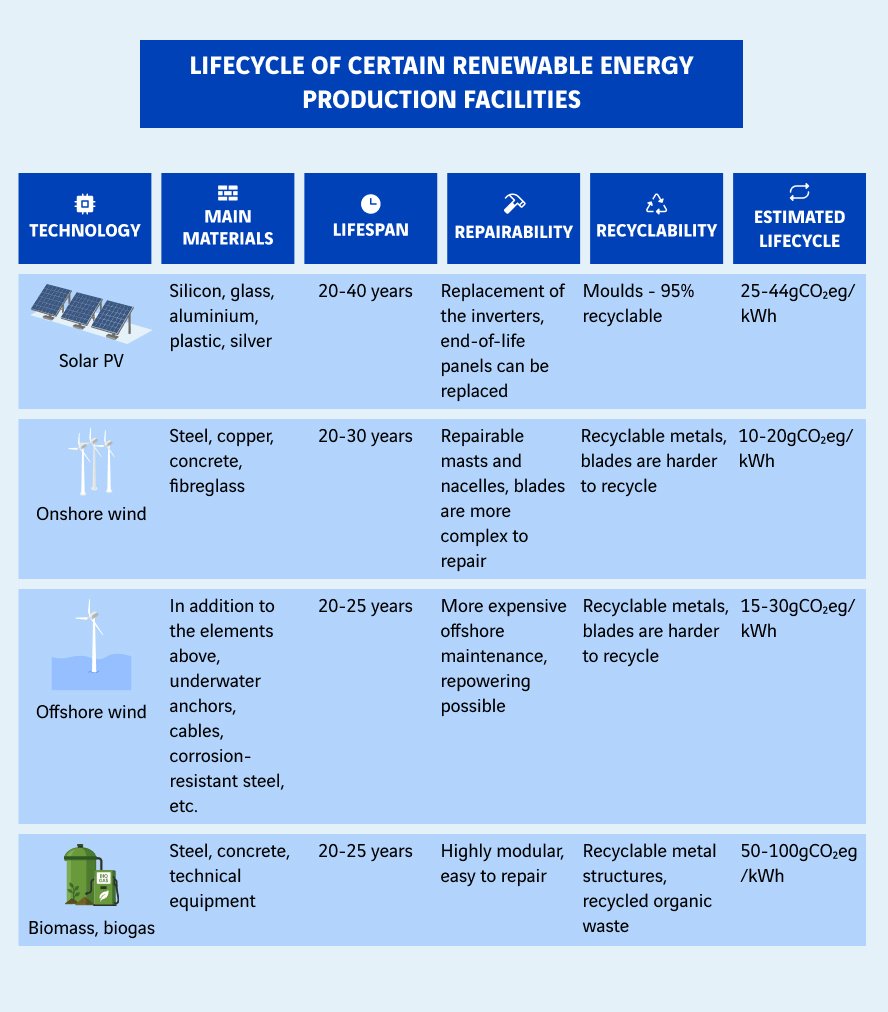

The total carbon footprint of a solar panel is estimated at around 25 to 44 g of CO2 per kWh, depending on where it was manufactured and the type of panel, meaning that it creates very little pollution. That is over 20 times less than coal, for example, which produces more pollution than any other resource with 1,060 g of CO2 per kWh.

25 to 44 g CO2eq/kWh

the carbon footprint of a solar panel.

Excellent results for wind turbines

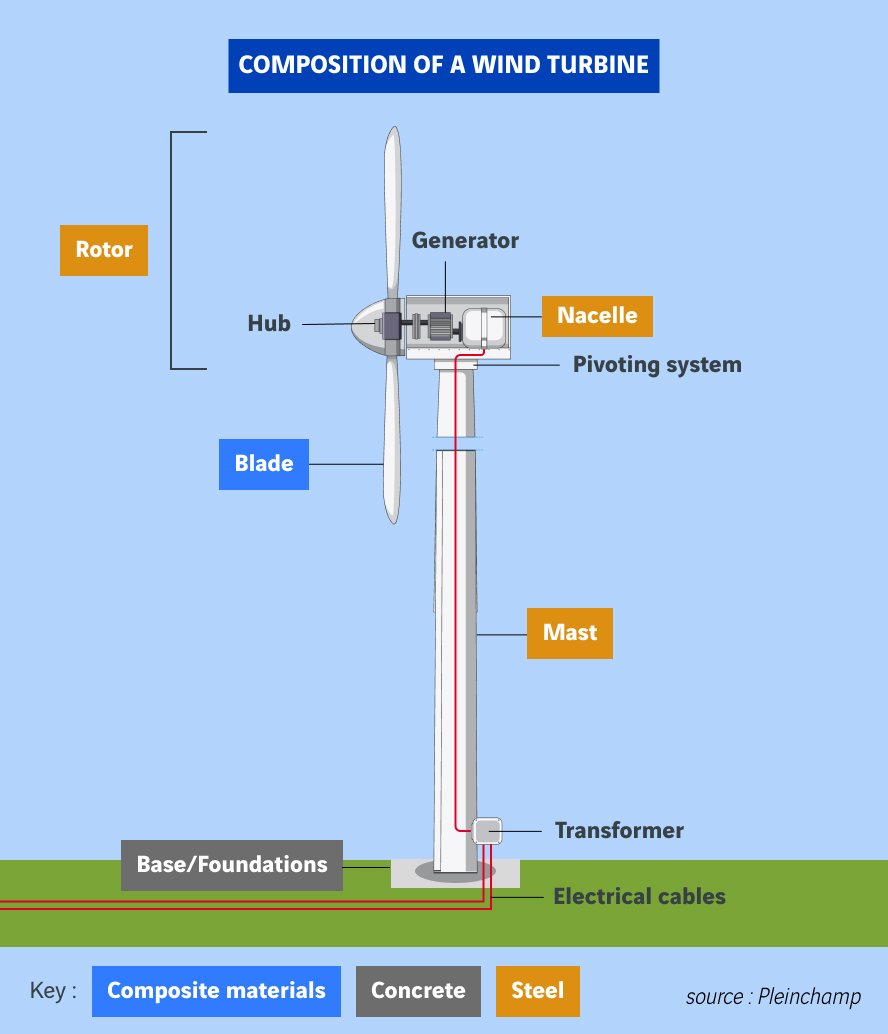

The most commonly used materials for building a wind turbine are concrete for the foundations and steel for the structure (nacelle, rotor and mast) in order to withstand both the weight of the structure and the force of the wind. Meanwhile, the blades are made from composite materials, such as fibreglass, which is also used to build boat hulls and aircraft fuselages. Manufacturing fibreglass requires high temperatures (1,500°C), which equates to high energy costs.

Assembling offshore wind turbines is often a major challenge, since they feature giant rotors and can produce up to 60% more energy than onshore wind turbines. To date, GE Renewable Energy’s Haliade-X stands as the most powerful wind turbine in the world (13 MW). It was designed and assembled in France in the extension to the Saint-Nazaire site built by VINCI.

Unfortunately, many wind turbine blades are landfilled or incinerated when they reach the end of their service life, since there are no suitable recycling processes, but recycling solutions are starting to emerge. For some materials, their components will be separated for reuse. Others will be crushed and incorporated into the manufacture of reinforced concrete.

Nevertheless, the carbon footprint of an onshore wind farm is between 10 and 20 gCO2eq/kWh, and between 15 and 30 gCO2eq/kWh for an offshore wind farm, which is an even better score than solar power systems!

Eco-design principles for an exemplary installation

Whatever energy source is chosen, efforts can be made to achieve the best possible carbon footprint as early as the facility’s design stage. Selecting local suppliers who use clean energy - even if this means a slight increase in the initial bill - can help improve the facility’s carbon footprint. Therefore, the grey energy and lifecycle concepts must be included when designing energy production solutions.

Lifespan and average production of renewable energy facilities

Wind turbines have an estimated lifespan of between 20 and 25 years. Regular maintenance obviously helps keep them in good condition and extend their service life. Observaero project developped by Omexom Renewable Energy Offshore (a VINCI Energies subsidiary) uses drones and artificial intelligence to provide an easier way of maintaining wind farms. Whereas rope access technicians previously had to be called in on a regular basis to check the condition of the wind turbine blades, the Observaero project uses drones, which are capable of taking photos of the facility’s key areas to easily detect potential problems. The images are processed with artificial intelligence to make the inspector’s job a lot simpler. This means that wind turbines requiring maintenance can be identified more quickly at a lower cost.

The lifespan of a solar panel is estimated at between 20 and 40 years, depending on its type and date of manufacture, bearing in mind that hindsight on the technology is still limited, since the first solar panels were generally installed in the 1990s. Manufacturers often consider that panels lose around 20% of their capacity after 25 years. However, the inverter, which transforms the direct current supplied by the panels into alternating current, needs to be replaced every 10 years.

Repowering, which refers to the process of replacing older power stations, is a strategy that can extend the service life of these structures. At a time when attempts are being made to limit land take, replacing instead of completely dismantling a production site makes perfect sense. For instance, an end-of-life solar power plant can have its panels replaced with much more efficient models, or wind farms can have their turbines swapped out for the latest generation versions. By way of example, repowering the Romanche-Gavet hydroelectric power plant in France has led to a 40% increase in the energy produced by the site.

Closer look at… a dismantling project

To truly achieve the energy transition, ageing production facilities must be dismantled to encourage the development of other types of energy that are kinder to the environment.

In 2024, VINCI Construction subsidiary Nuvia was awarded a contract to dismantle units 1 and 2 of the Ringhals nuclear power plant in Sweden. Over a six-year period, Nuvia will remove, inspect and sort the radioactive and other materials currently inside the reactor buildings. Ringhals’ reactors 3 and 4 continue to supply about 12% of the country’s electricity.

Sources :

Courrier international – « Pourquoi la Chine construit une ligne électrique à ultra-haute tension ? ». https://evenements.courrierinternational.com/transition-ecologique/pourquoi-la-chine-construit-une-ligne-electrique-a-ultra-haute-tension/

VINCI - “VINCI signs the first public-private partnership (PPP) contract for electricity transmission in Australia”. https://www.vinci.com/en/newsroom/press-releases/vinci-signs-first-public-private-partnership-ppp-contract-electricity

Connaissance des énergies – « Qu’appelle-t-on l’énergie “grise” ? ». https://www.connaissancedesenergies.org/questions-et-reponses-energies/quappelle-t-lenergie-grise

Engie – « Comment sont fabriqués les panneaux solaires ? Tout savoir ». https://mypower.engie.fr/conseils/panneaux-solaires/caracteristiques-panneaux-solaires/comment-sont-fabriques-les-panneaux-solaires-tout-savoir.html#1

Statistica – « Panneaux solaires : la Chine domine la production mondiale ». https://fr.statista.com/infographie/29926/industrie-panneaux-solaires-production-mondiale-par-pays-et-regions/

ECOinfos énergies renouvelables – « Les émissions de CO2 par source d’énergie renouvelable (ACV) ». https://www.les-energies-renouvelables.eu/conseils/bilan-carbone/bilan-carbone-emission-co2-source-energie-renouvelable/

eMAG VINCI – “Offshore wind power: The global situation”. https://www.vinci.com/en/emag/offshore-wind-power-global-situation

Hubency – « Comment recycler la fibre de verre ? ». https://www.hubency.com/dechets-valorises/dechets-inertes/fibre-de-verre/

ECOinfos énergies renouvelables – « Les émissions de CO2 par source d’énergie renouvelable (ACV) ». https://www.les-energies-renouvelables.eu/conseils/bilan-carbone/bilan-carbone-emission-co2-source-energie-renouvelable/

Hellio – « Quelle est la durée de vie d'un panneau solaire ? ». https://particulier.hellio.com/guide-solaire/fonctionnement/duree-vie-panneau-solaire

Leonard - “OBSERVAERO: drones and AI to inspect wind turbines”. https://leonard.vinci.com/en/observaero-drones-and-ai-to-inspect-wind-turbines/

Leonard - “Will repowering power up the energy transition?”. https://leonard.vinci.com/en/will-repowering-power-up-the-energy-transition/

VINCI - “VINCI wins contract to dismantle nuclear reactors in Sweden”. https://www.vinci.com/en/newsroom/press-releases/vinci-wins-contract-dismantle-nuclear-reactors-sweden

Subscribe

Stay tuned : receive our newsletter

Every quarter, discover new articles, exclusive features and experts' views delivered straight to your inbox.

Most viewed

Explore more

Marina Lévy - Companies at the heart of ocean conservation issues

Marina Lévy, oceanographer, research director at the CNRS and ocean advisor to the president of the French National Research…

Access to water in Africa: persistent challenges despite major progress

When looking at the situation of safely managed water supplies in Africa, the glass could be seen as half full, rather than…

Building with and for nature

Whether creating barrages, stripping away topsoil, cutting down trees or digging channels, humans have spent thousands of…