Breaking stereotypes about mining work: human challenges at a unique worksite

VINCI is one of the main constructors of what will be the world’s longest rail tunnel. The worksite presents multiple technical, logistical and human challenges that include unexpected geological conditions encountered when crossing the Alps, investment in one-of-a-kind machinery during the first two years, extremely restrictive logistics, industrial management of millions of tonnes of excavated material, and a 20-year shortage of workers skilled in traditional drilling and boring techniques. Interview with Estelle Vinter, head of HR for the site at the Civil Engineering division of VINCI Construction in France.

Why has human resources management been such a crucial element of the Lyon-Turin project?

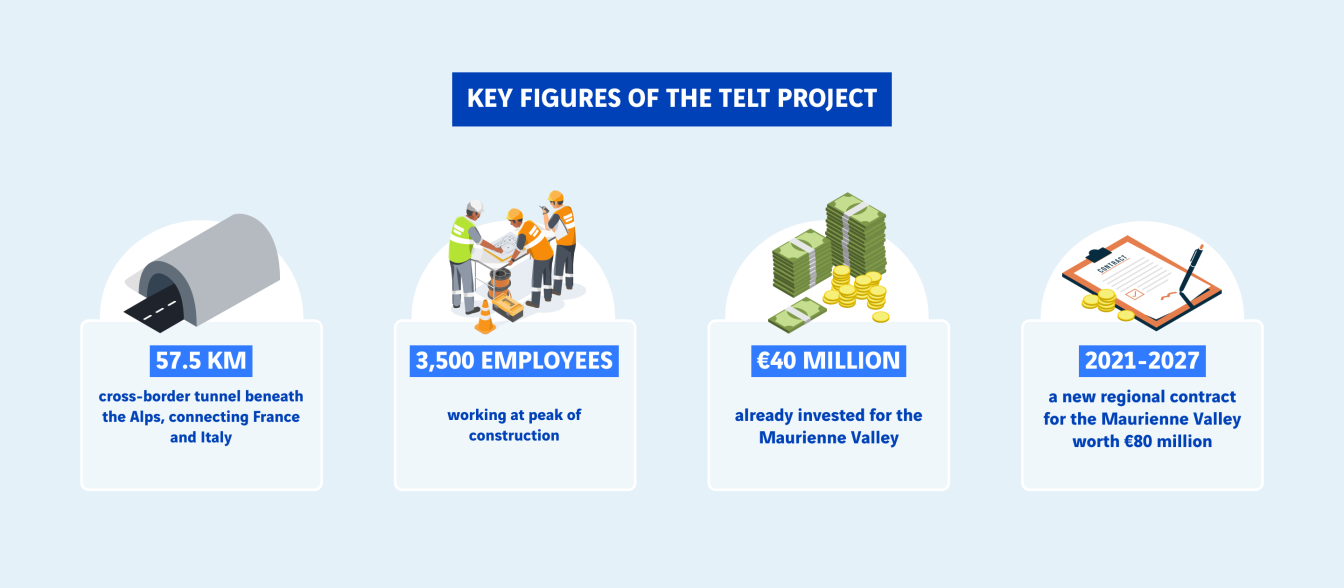

In terms of scale and complexity, the worksite for the cross-border section of the new Lyon-Turin rail line is a one of a kind. With the cost of construction estimated to exceed 11 billion euros and work set to last 10 years, this is one of the most significant pieces of infrastructure ever built in Europe. The 57.5-km Mont-Cenis base tunnel is the longest rail tunnel in the world, running from the Maurienne valley in France to the Suse valley in Italy. At its peak it is estimated that between 4,000 and 5,000 people will be working at 10 operational worksites running simultaneously. This gives an indication of the massive need for workers. In terms of operational worksites 6&7 that I look after – digging one of the longest sections of the base tunnel (around 46 km of galleries) – there were only about 20 of us in 2021. Two years later the team had grown to over 1,300, including 900 skilled workers, almost 300 of them miners with skills that have been almost totally lost. Some of the challenges, such as working away from home, accommodation and social life, are shared by colleagues at the other operational worksites managed by VINCI companies (underground structures and ventilation shafts at Modane, and managing, treating and recycling excavated materials on the French side).

The shortage in France of drilling and blasting skills is a real problem when you consider that working 24/7 simultaneously at 12 locations will require considerable human resources, with miners particularly in demand.

What recruitment challenges do you face?

For some roles demanding little in the way of previous qualifications, the biggest challenge is finding enough candidates. The local labour pool is not very extensive and is already close to capacity. Savoie is one of France’s most buoyant departments and the local unemployment rate was already below the national average before the TELT project started. This means we have to recruit from all over France, even internationally from the other side of the Alps with help from leading Italian construction specialist WeBuild, our partner in the consortium. But there is stiff competition from other employers. All operational TELT worksites have the same pressing need for workers, as do all other major sites under way in France and Italy.

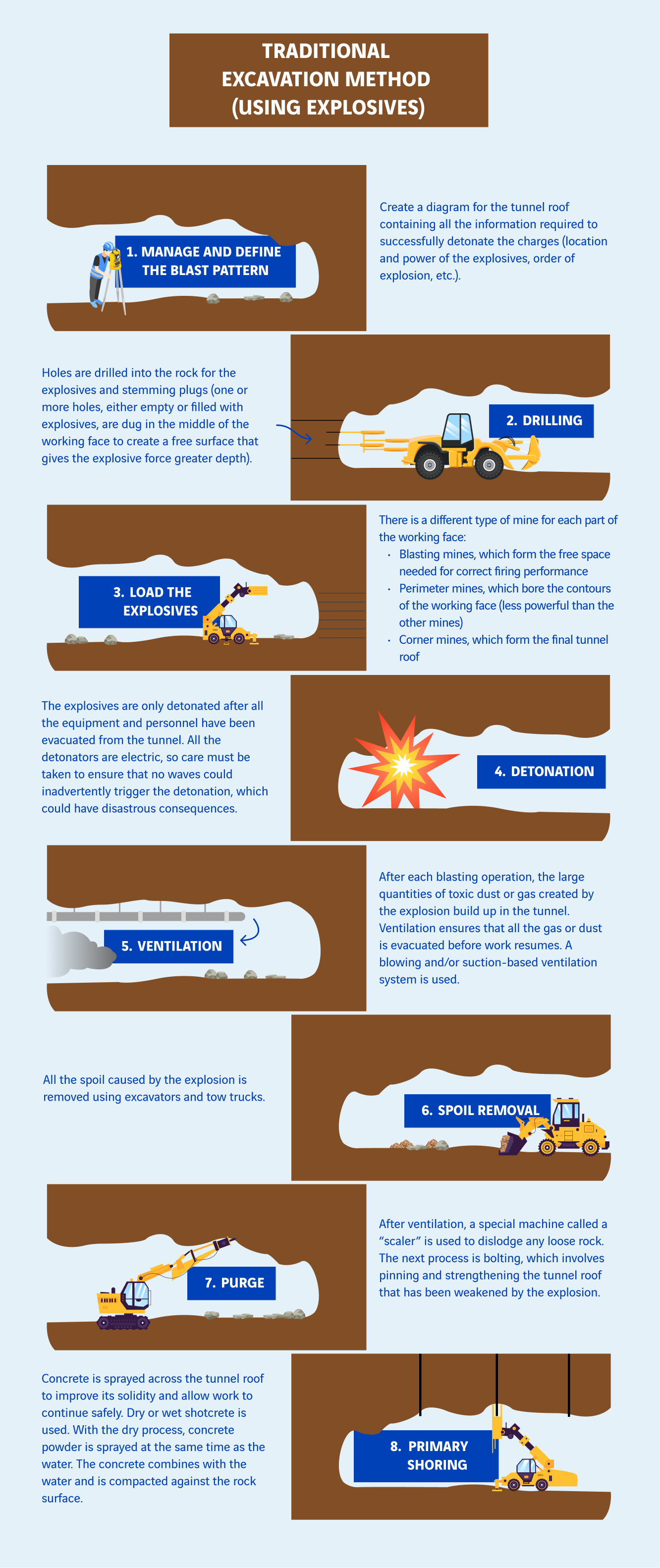

And as well as finding enough people there is also the question of skill sets. Half the tunnels are being dug conventionally, by blasting. But it has been a long time since the last major project of this type in France: there are not that many skilled and experienced miners with the accreditation needed to handle explosives. We have to work with specialist agencies to identify and recruit these specialist profiles, and we have of course provided training for miners and operators in the use of all the specialist site machinery.

Does the tough nature of the work make recruitment harder?

It is true that working underground involves dealing with a demanding environment in terms of restricted space, humidity and temperature. But today's working conditions are nothing like the image some people still have of mining. A good part of our work involves promoting our job opportunities at employment forums by breaking down mining stereotypes inherited from the 19th century! Enormous resources are focused, in particular, on the safety of our teams. The worksite for the Mont-Cenis base tunnel is setting new safety standards, with a very large number of innovative requirements, including: ventilation and air conditioning in galleries to control ambient temperatures, permanent gas measuring, advanced technology tools and machinery, and real-time geolocation of everybody in tunnel galleries. All miners work less than a kilometre from a secure refuge supplied with a water and oxygen in the event of fire. But above all, underground work is performed by experts and enthusiasts, it is highly regarded and very rewarding, including in terms of salary.

How are the worksites organised?

This is one of the ways that we attract talent. The worksite is operational 24/7, with three team shifts a day. But work schedules are organised on a “6-4” pattern (or even “4-4” for some teams), meaning six days on and four consecutive days off. Due to the worksite’s remote location, this is a major advantage for the journeymen, since those who live far away can more easily go home after work than if they were on a conventional “5-2” shift.

Providing on-site accommodation is also high on our priority list. Normally, employees would deal with this aspect themselves, but the sheer magnitude of the TELT project is tending to overwhelm the valley’s ability to house them all, so we are actively working alongside the region’s stakeholders to set aside accommodation. Plans to build a site hotel are currently being examined with the customer TELT, which would serve all the project’s operational worksites and could potentially be kept after the project has been delivered.

How much new hire onboarding and training is involved in your HR work?

It is absolutely central! Alongside our customer, we are part of a programme called Grand Chantier that is backed by the state, the Auvergne-Rhône-Alpes region and the Savoie department. It is a vast programme of actions to embed the project into the local region in terms of recruitment, training, onboarding workers and working with local and regional businesses. As well as accommodation, transport and quality of life, another major aspect of our work relates to training in our activities and our occupational health and safety culture. Working with public employment service France Travail we have designed a training pathway for miners’ assistants, which has already produced seven classes of new trainees to assist miners with preparations and basic tasks, help set up tools, etc. And because miners’ assistants will join teams of experienced miners they will have the chance to quickly train for promotion to roles as miners, perhaps even driller-blasters, paving the way for real opportunities in the future.

Our tunnel segment plant in La Chapelle offers another training pathway, this time focused on people excluded from the labour market. We deliver training on topics such as the fundamentals of safety or materials handling, enough for them to get started. Ultimately, a project on the scale of TELT provides a unique opportunity for us to help people discover our activities, change they are perceived, and onboard and train an entire new generation of skilled workers.

Subscribe

Stay tuned : receive our newsletter

Every quarter, discover new articles, exclusive features and experts' views delivered straight to your inbox.

Most viewed

Explore more

Marina Lévy - Companies at the heart of ocean conservation issues

Marina Lévy, oceanographer, research director at the CNRS and ocean advisor to the president of the French National Research…

Access to water in Africa: persistent challenges despite major progress

When looking at the situation of safely managed water supplies in Africa, the glass could be seen as half full, rather than…

Building with and for nature

Whether creating barrages, stripping away topsoil, cutting down trees or digging channels, humans have spent thousands of…