Transforming mobility in Greater Paris: an engineering and social challenge

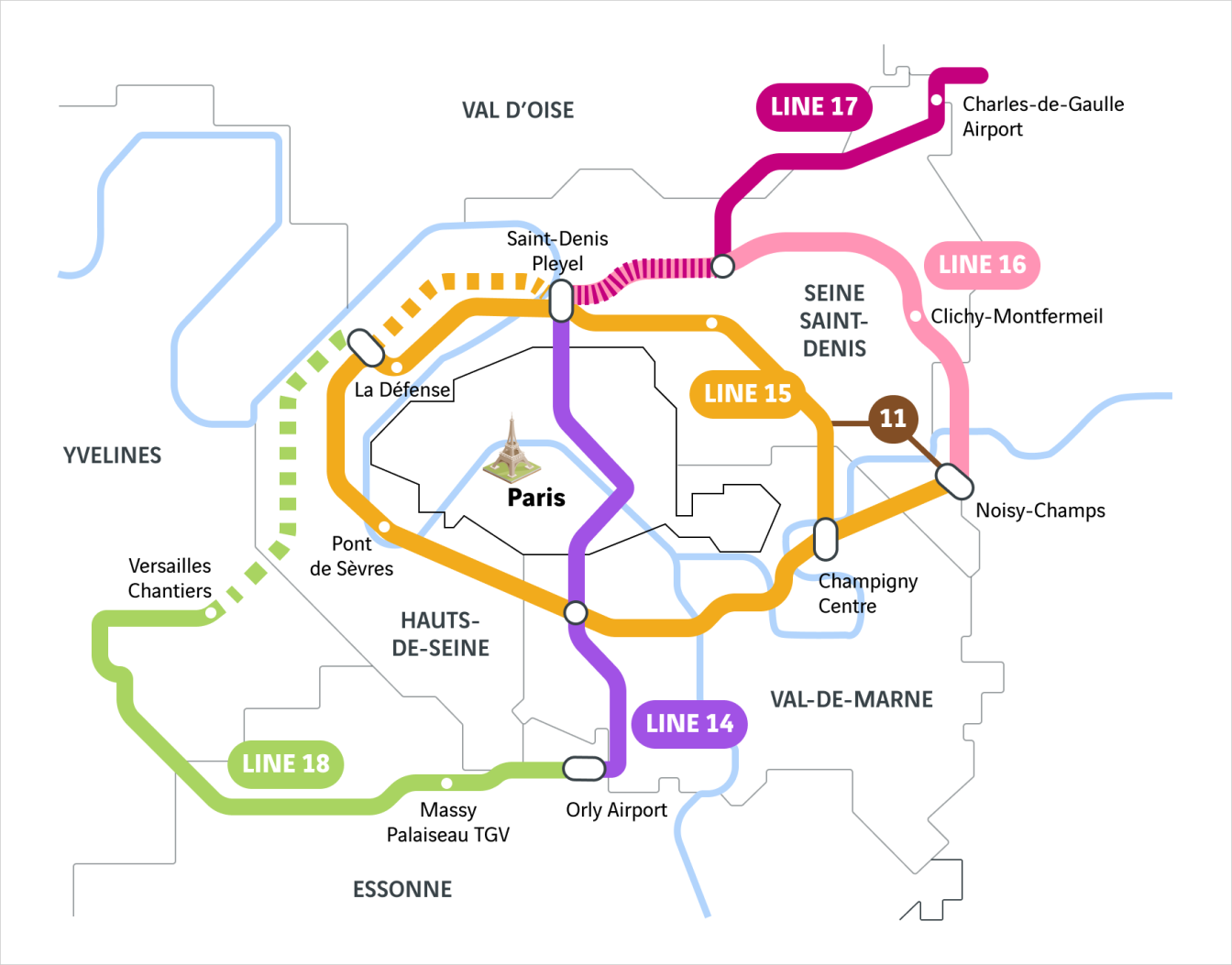

An underground revolution is currently sweeping through the heart of the Île-de-France or Greater Paris region. Home to over 12 million inhabitants, the authorities are determined to overhaul the region’s mobility infrastructure to improve transportation and access for the different communities while creating new opportunities. This ambition is reflected in the Grand Paris Express project with its 200 km of new tracks and 68 stations. Several complex technical, logistical, environmental and social challenges lurk beneath the surface of this gargantuan project.

In the same report

The ambitions behind the Greater Paris project

Greater Paris: inventing the city of the future

Technical challenges: build inside and beneath a dense metropolitan area

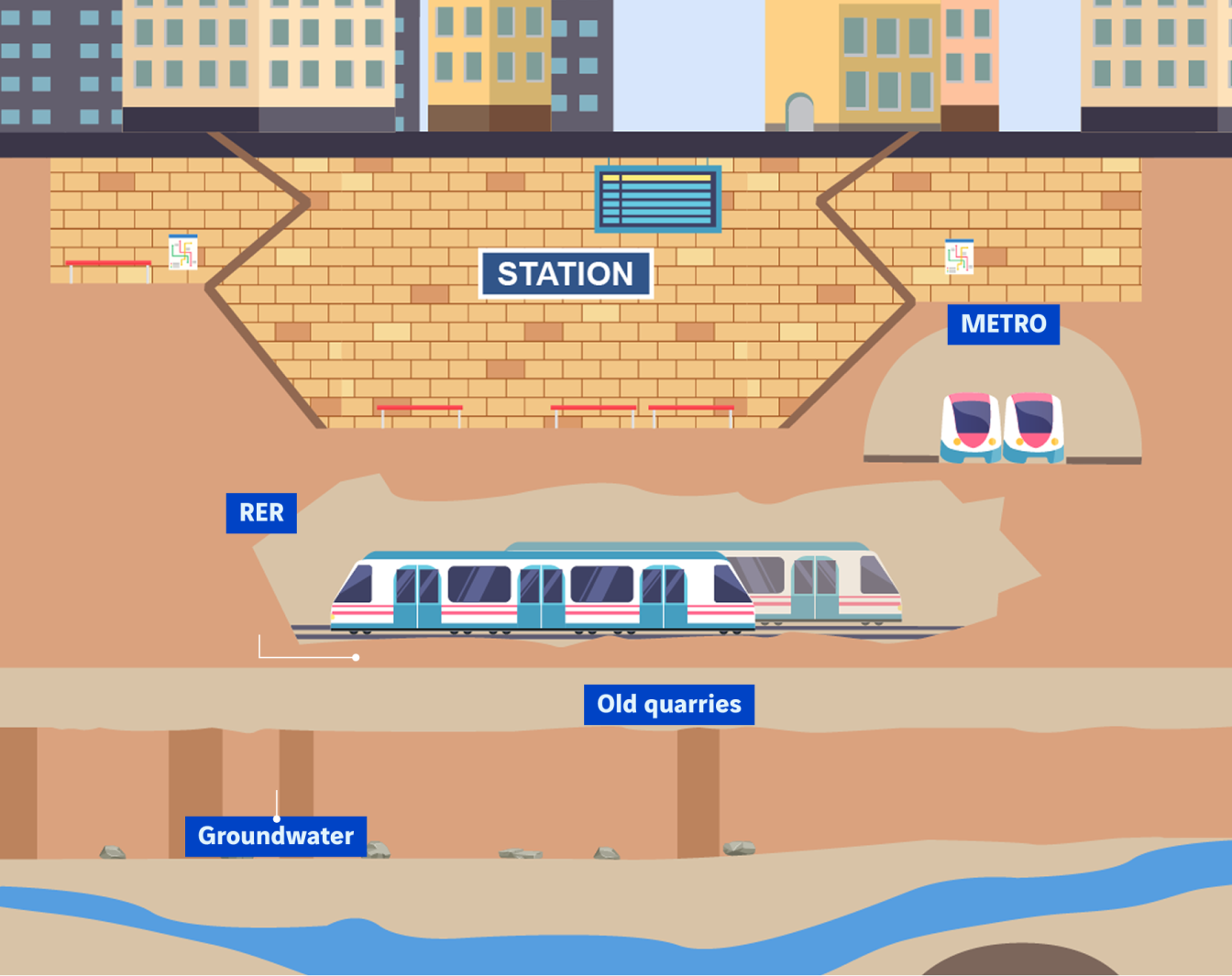

Building an underground transport system in such a dense urban area as Greater Paris is nothing less than a large-scale technical challenge. Digging beneath the region’s surface reveals an especially complex subsoil structure comprising sensitive clay, groundwater and old quarries, without forgetting the many networks snaking their way through the ground, such as sewer pipes, cables and underground transport tunnels. Every operation involving the subsoil must be carried out with extreme levels of precision to avoid undermining the integrity and solidity of the buildings and infrastructures on the city’s surface. In heavily populated urban areas, floor space is a rare commodity, so work must be performed in a way that minimises any disruption for local residents.

Tunnel boring machines: from tradition to innovation

Ever since ancient times, digging tunnels has been a technically challenging endeavour. Tunnels were originally used to carry water or create communication channels, and were dug using basic, but labour-intensive techniques.

With the advent of the industrial revolution, the process for boring railway and mining tunnels gained pace as new tools came on the market. But the invention of the tunnel boring machine was the greatest game-changer when it came to underground construction. In the 1980s, these machines measured over 100 metres in length and 19 metres in diameter, and quickly became essential for transport and urban infrastructure projects.

Today’s TBMs feature cutting-edge technology and continue to raise the performance bar ever higher, with automated systems, artificial intelligence and data sensors for quick and safe tunnelling. VINCI Construction’s Tunnel Factory is specifically focused on keeping the Group ahead of the innovation curve in the underground works sector.

The logistical challenges in coordination colossal worksites

Thousands of workers and hundreds of contractors are working on several worksites across Greater Paris at the same time, around 20 tunnel boring machines are concurrently in operation, millions of tons of earth must be evacuated... needless to say, the Grand Paris Express project represents a daunting logistical challenge.

A matter of coordinating people and machines…

Building 200 km of new tracks and 68 stations calls for the different stages to be perfectly synchronised, such as boring the tunnels, building the stations, fitting the equipment, and installing the electrical and ventilation systems. The building information modelling (BIM) software is connected to a database and represents an invaluable tool for ensuring cooperation. It allows employees to access the latest worksite information in real time using various devices (PCs, tablets, smartphones, etc.). Therefore, all the different teams see the same consistent information.

The project’s integrated design & build approach

Unlike a traditional worksite where contractors simply follow the blueprints produced by other parties to the project, the design & build method incorporates both phases into the same process. In other words, contractors are responsible for both designing and building the structures. A prime example is the first section of the Line 15 West, which has been awarded to a consortium including several VINCI Construction and VINCI Energies subsidiaries. This approach helps anticipate difficulties, improves cost certainty, accelerates decision-making through direct communication between the designer and builder, and streamlines the process of coordinating work.

… and optimising workflows

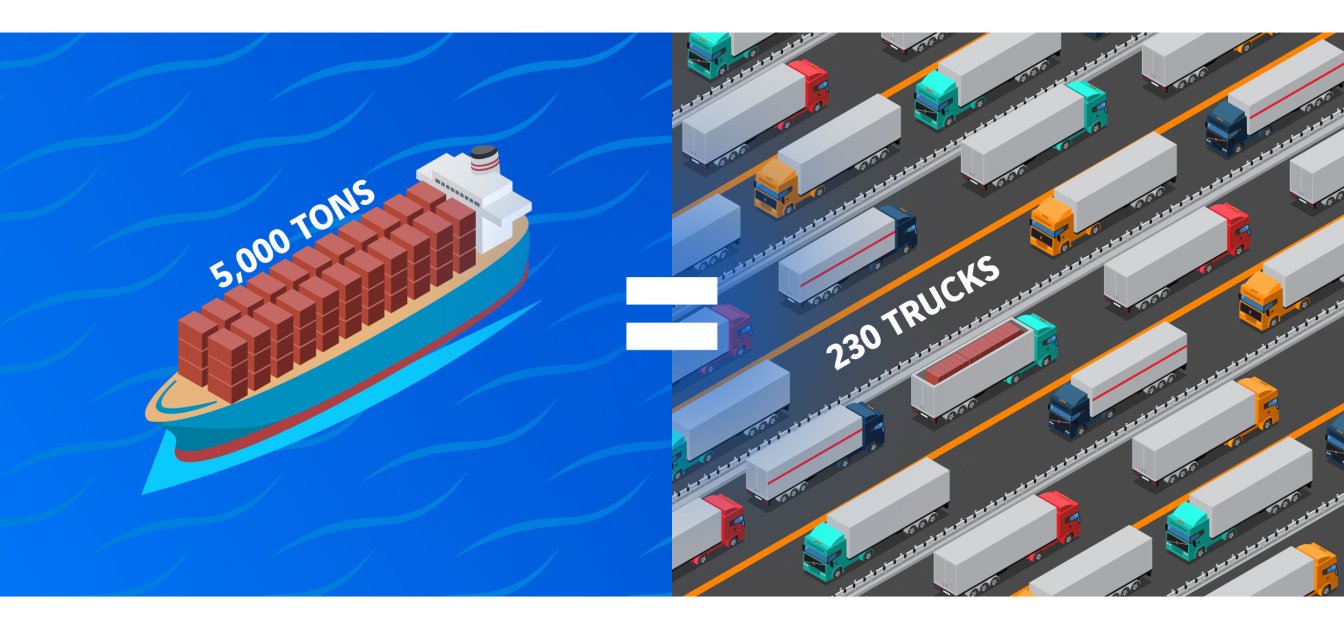

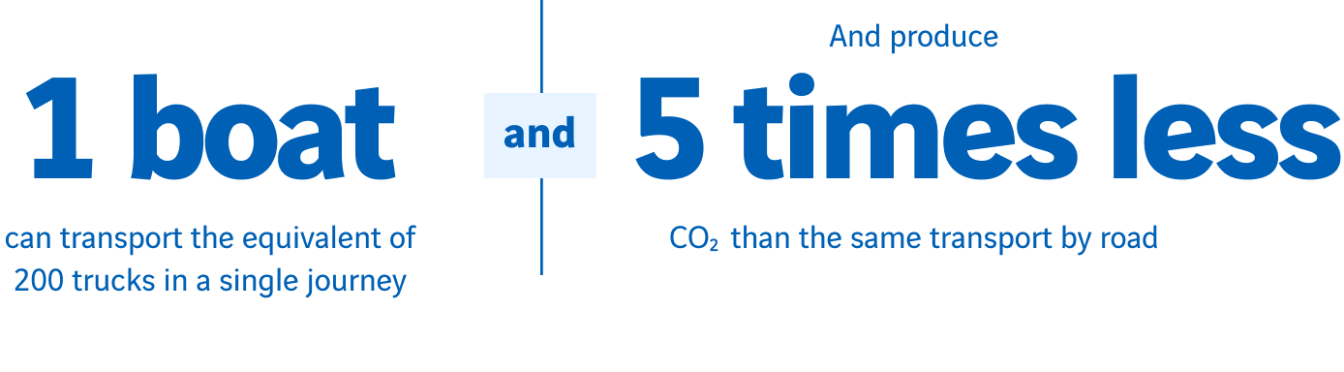

Grand Paris Express needs to keep work forging ahead, while preserving everyday urban life. To avoid gridlocked streets across the city and prevent vehicles from jamming restricted-access areas, specific off-peak times have been introduced for delivering materials. A combined road, rail and river transport strategy for supplying materials and evacuating spoil is also minimising the impact on road traffic and the environment, bearing in mind that a ship with a 5,000 ton cargo means 230 less trucks on the road. Logistics hubs have been set up in strategic points across the region and are used as both sorting and transit centres for delivering supplies and removing spoil as part of a just-in-time approach, which reduces the amount of traffic at urban sites.

Environmental challenges: substainable construction

Although worksites generate CO2 emissions, the project is designed to ultimately have a positive global impact on the environment. By 2050, the network is expected to reduce the amount of CO2 equivalent by 14.2 million tons.[1]

Fabrique du Métro: life-size innovations

Housed in a converted former warehouse in Saint-Ouen-sur-Seine, the Fabrique du Métro is not unlike a museum and is designed to spotlight the innovations behind the Grand Paris Express project. Above all, it is a venue for collaboration that brings together all the parties involved in the project, such as architects, engineers, building contractors and future operators. The Fabrique du Métro is also a laboratory for testing the equipment that will enhance the traveller experience. Whether signage in the stations or access control systems, every component is tried and tested before it is installed. VINCI carries out various experiments at the site, especially on low-carbon materials. The Fabrique du Métro also acts as a showcase by giving the public an insight into the sustainable solutions that will shape the rapid transit system of tomorrow’s world.

Shrink the carbon emissions generated by the works

Société des Grands Projets, which is the public company in charge of designing and building the transport network, is paying special attention to the impact that construction work on the new underground rapid transit systems is having on the environment.

- Optimise the process for transporting materials

One of the main strategies for driving down emissions involves improving the process for transporting materials and spoil. Société des Grands Projets and its partners, including VINCI, are counting on a combined rail-river transport model to avoid the use of trucks [2] and thereby cut CO2 emissions.

- Build with low-impact materials

Concrete is one of the key materials for building infrastructures, but it is also responsible for producing around 70% of a worksite’s carbon emissions. Therefore, VINCI is promoting the widespread use of Exegy® low-carbon concrete, especially the Exegy® Ultra range, which can lower emissions by 75% compared to conventional concrete.

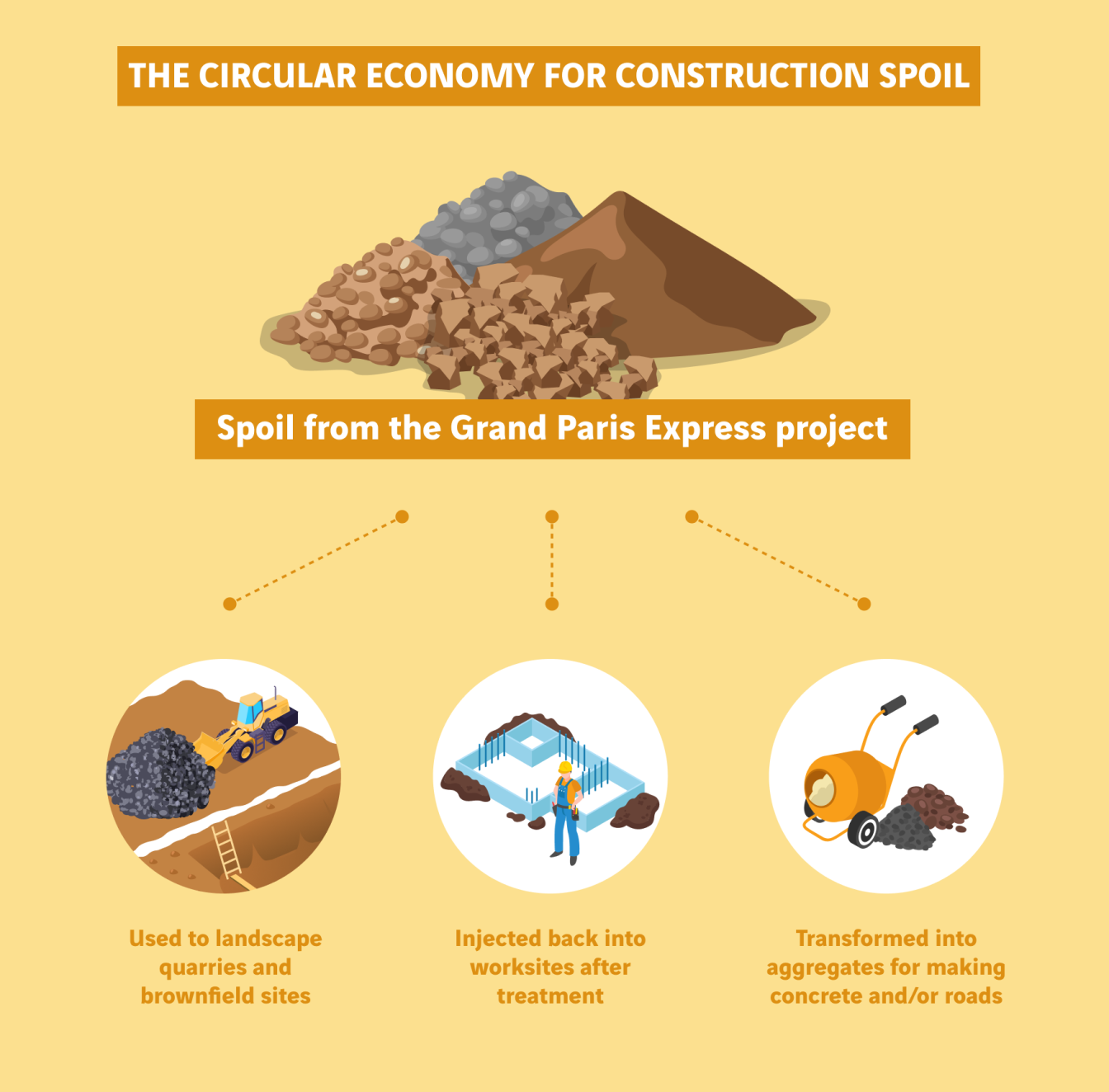

- Recycle and reuse spoil

The worksites within the Grand Paris Express project are expected to generate a considerable amount of spoil, which has been estimated at 43 million tons. The goal is to recover at least 70% of that material. To reach this target, Extract (a VINCI Construction subsidiary) is involved in the earliest stages of the worksite to determine the composition of the materials and their reuse potential, so that the appropriate recycling processes can be chosen. Once the inert soil has been sorted, it is reused to landscape quarries and brownfield sites, or injected back into the worksites after treatment, which avoids having to tap into new natural resources. Some of the spoil is also transformed into aggregates and reused to make concrete or build roads. VINCI subsidiary Eurovia is capable of providing end-to-end solutions where delivery trucks supply aggregates (especially aggregates containing recycled materials) before returning with a full load of spoil, as well as solutions for recovering certain types of excavated material. These reuse and transformation strategies mean that the spoil is considered to be a resource in its own right, which demonstrates how the worksites within the Grand Paris Express project have adopted the principles of the circular economy.

Subtainable, energy-efficient infrastructures

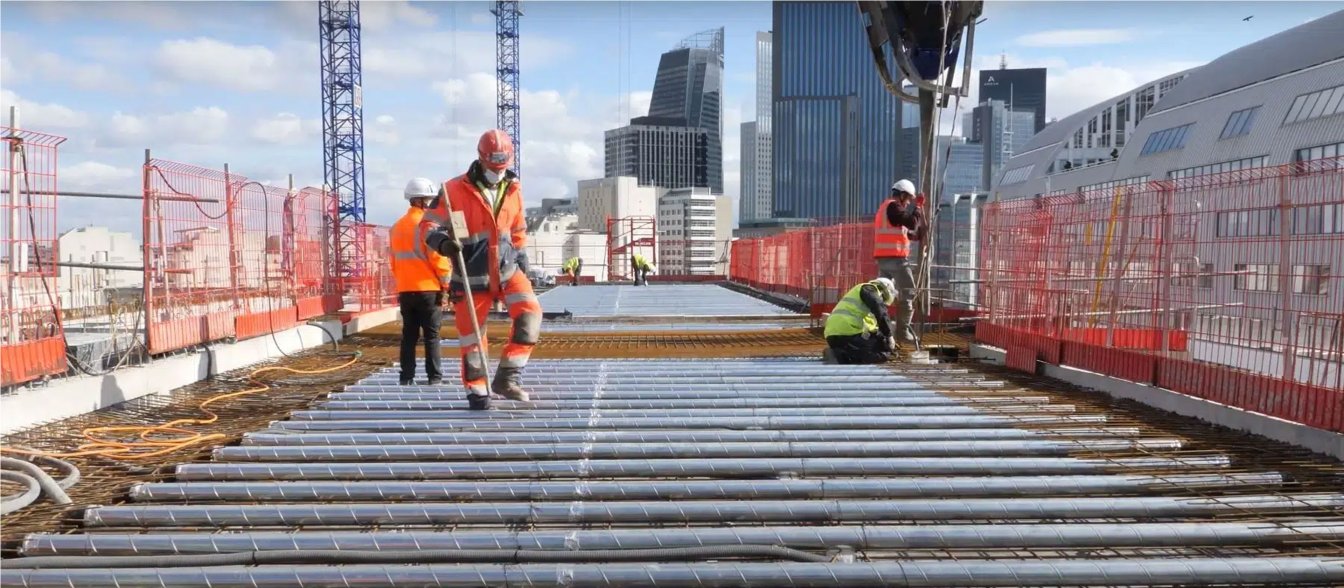

The environmental impact of the Grand Paris Express project is not just restricted to the construction works. The subsequent operation of its rapid transit systems needs to embrace sustainability by anticipating the challenges posed by climate change. The Grand Paris Express stations and structures are designed to be energy-efficient. By way of an example, centralised technical management systems will be installed to improve energy consumption in the buildings and infrastructures. VINCI Construction and VINCI Energies have teamed up to create the innovative GreenFloor® HVAC system, which draws air into the concrete slabs before releasing it using both radiation and convection from the ceiling. This technology uses very little energy and provides substantial space savings.

The social challenges of a regional project

Grand Paris Express is more than just a major technical achievement, since the primary aim is to improve life for society by changing the very face of the city.

Restore balance across the region...

Some of the region’s outlying districts are affected by a lack of connections with the rest of the metropolitan area. The situation restricts their inhabitants’ access to employment, training, services and leisure activities. Grand Paris Express is delivering a tangible response to this issue by redesigning the connections between the region’s different suburbs and reducing the need to take journeys that run through central Paris. With its 68 new stations and interconnected lines, the network is streamlining travel and closing the distance that separates inhabitants from the job markets. For example, the time taken to travel between Noisy-Champs and La Défense will be halved from 70 minutes to just 35 minutes, while the journey between Palaiseau and Orly will be cut by a factor of four from an hour to less than 15 minutes.[3]

The new stations are also being accompanied by an ambitious urban redevelopment plan that involves creating new dynamic and sustainable districts. By 2030, close to 250,000 homes should be built near the new stations, together with shops, public amenities and green spaces. The aim is to promote a balanced development programme across the metropolitan area by creating attractive communities outside central Paris, ensuring that opportunities are divided evenly across the region and thereby reducing inequality.

...and forge stronger social ties

The sheer scale of the Grand Paris Express initiative is radically changing the living environment for the region’s inhabitants. This new form of mobility promotes social cohesion. The new districts built around the new stations include homes, shops, public amenities and green spaces, which improves social interaction and diversity. Projects are designed to encourage socialisation, with shared spaces, cultural centres and facilities to foster greater interaction between inhabitants.

Worksites driving jobs and employability prospects

The work involved in leading the Grand Paris Express project is also powering the region’s economy by generating thousands of direct and indirect jobs in many different sectors.

- 15,000 direct jobs in construction, engineering, project management, etc.

- 120,000 indirect jobs in urban design, retail, services, etc.

To ensure that the widest number of people can share in the project’s benefits, Société des Grands Projets has stipulated that 5% of all hours worked at the various worksites must be performed by people on back-to-work schemes. VINCI Construction is dedicating 7 to 10% of its worked hours to such schemes through the ViE programme (VINCI Insertion Emploi).

The Chantiers et territoires solidaires endowment fund

In 2016, VINCI Construction and VINCI Energies created this fund, with a helping hand from the Fondation VINCI pour la Cité, to support local initiatives relating to worksites within the Grand Paris Express project:

- organisation of worksite visits to get inhabitants involved and better explain the project’s aims

- employees volunteering to take part in local

- supporting projects serving the general interest

The success of such a project hinges on the ability to develop innovative technologies while meeting social and environmental ambitions. VINCI is contributing to the process by spearheading solutions that address the many different challenges, whether technical, logistical, environmental or social.

Sources

[1]Une nouvelle stratégie pour consolider les bénéfices environnementaux du Grand Paris Express (Société du Grand Paris, octobre 2021)

[3] A bord du supermétro du Grand Paris : vos temps de trajet en 2030 (leparisien.fr, novembre 2018)

Subscribe

Stay tuned : receive our newsletter

Every quarter, discover new articles, exclusive features and experts' views delivered straight to your inbox.

Most viewed

Explore more

Marina Lévy - Companies at the heart of ocean conservation issues

Marina Lévy, oceanographer, research director at the CNRS and ocean advisor to the president of the French National Research…

Access to water in Africa: persistent challenges despite major progress

When looking at the situation of safely managed water supplies in Africa, the glass could be seen as half full, rather than…

Building with and for nature

Whether creating barrages, stripping away topsoil, cutting down trees or digging channels, humans have spent thousands of…